Thanks to the steady efforts in the research and development of new technologies and in the increase (expansion) of its own production capacity, Berti is now a byword for Ecology and highest quality.

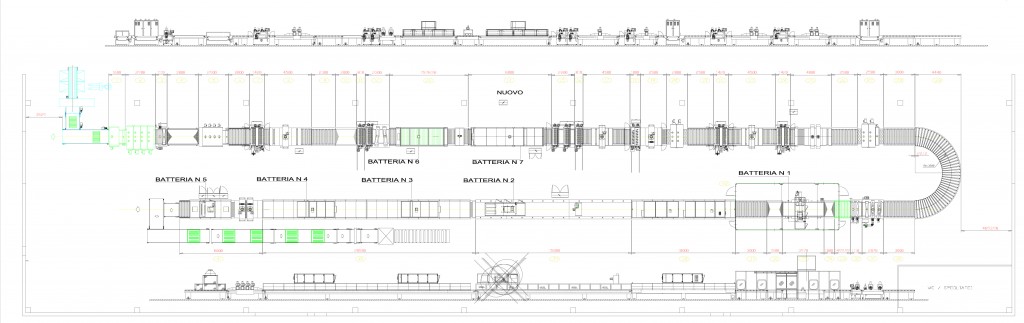

Starting from January 2012, in fact, Berti will operate a new water based varnishing system: it’s a 250 meter long lacquering line that has no comparison in the panorama of the european wooden floors producers. This system was installed in the new plant, using the most up to date technologies created for meeting the needs of wooden processing and finishing , with technical solutions that grant reliability and high quality level of the products.

The product moves across the painting line at 10 meter/minute speed, going through all the different phases including:

- Calibration,

- Drying in UV oven,

- Plastering,

- Sanding,

- Brushing,

- Water based stain (where foreseen),

- Drying of the water based stain (where foreseen),

- Plastering,

- Slight sanding,

- Plastering,

- Slight sanding,

- Curtain coat finishing,

- Drying in UV oven.

Now after 25 minutes and 14 steps, the product is ready for the final production phase: the wide planks bevelled are ready to be packed, while the square edge products are subject to the profiling phase.

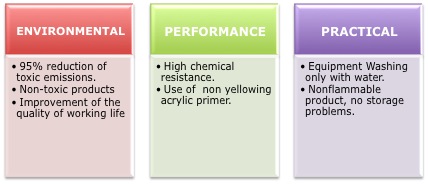

Berti decided to side with Environment, keeping an holistic approach. For this reason the production department and the plants enjoy now a higher protection: toxic emission in the environment has been almost eliminated. How we have reached this result?

Starting from January 2012 Berti Pavimenti Legno will be the only producer in Italy using a special water based lacquer for the wooden floor finishing. This particular lacquer , used in the new varnishing line, allow us to have a product that maintains unchanged its own characteristic in terms of resistance, quality, hardness and visual aspect. We have improved the quality of working life and the environmental impact of our production process, by reorganizing the production plant, increasing the production capacity and maintaining unchanged, in the meantime, our high quality level.

Our choice of renewal agrees with our will to safeguard more our human resources, that every day work in Berti plants, as well as the environment surrounding us. The desire to produce environmentally friendly products describe us as a company having an active role in the environmental protection.

Berti products, Lux, Antico and Basic, produced with the new water based lacquer, are now able to meet the existing production needs as well as the new environmental requirements. The water based varnishing line is arranged to develop also the bleached and natural effect finishings, as well as BertiStudio colors, that are ever-changing. Berti wooden floors with water based lacquer are environmentally friendly products: they can boast a 95% reduction of toxic emissions, in comparison with the poly- acrilic lacquer, maintaining in the meantime a high professional quality level. Their quality is confirmed by Berti.

- Water based lacquer advantages

About this topic you can also read the post:

“Berti gives the final farewell to the historic varnishing system”

And to finish take a look at this video that presents the new varnishing plant. The images are really attractive: come with us and see with your eyes how we work at Berti!

Print